Within the framework of ENERXICO, advanced modelling tools for high-fidelity combustion simulations are developed to study the use of renewable fuels in future sustainable transportation systems. This includes both biofuels and power-to-liquid fuels, the so-called ‘e-fuels’, for which combustion characteristics need to be further understood before they can be applied in combustion systems with optimal efficiency and with minimum pollutant emissions.

The reliable use of these computational models demand for extensive validation from highly controlled experiments, such as the ones performed within ENERXICO. These experiments replicate the operating conditions that such advanced fuels will find in the combustion chamber of an engine in an optically accessible vessel. This means filling up a test volume with air of controlled composition at high pressure (up to 150 bar) and temperature (up to 730ºC), and injecting the fuel through a single-hole injector at realistic injection pressure (1500 bar). Compared to a real engine, where multi-hole injectors are used, and wall interaction as well as piston movement can occur, this is a much more simplified environment. However, conditions of the experiments are highly controlled, and highly advanced optical diagnostic tools can be used to quantify parameters that cannot be obtained from a normal operation of the engine. These results can shed light on the performance of the different fuels to properly characterise the injection, evaporation, mixing and combustion respectively.

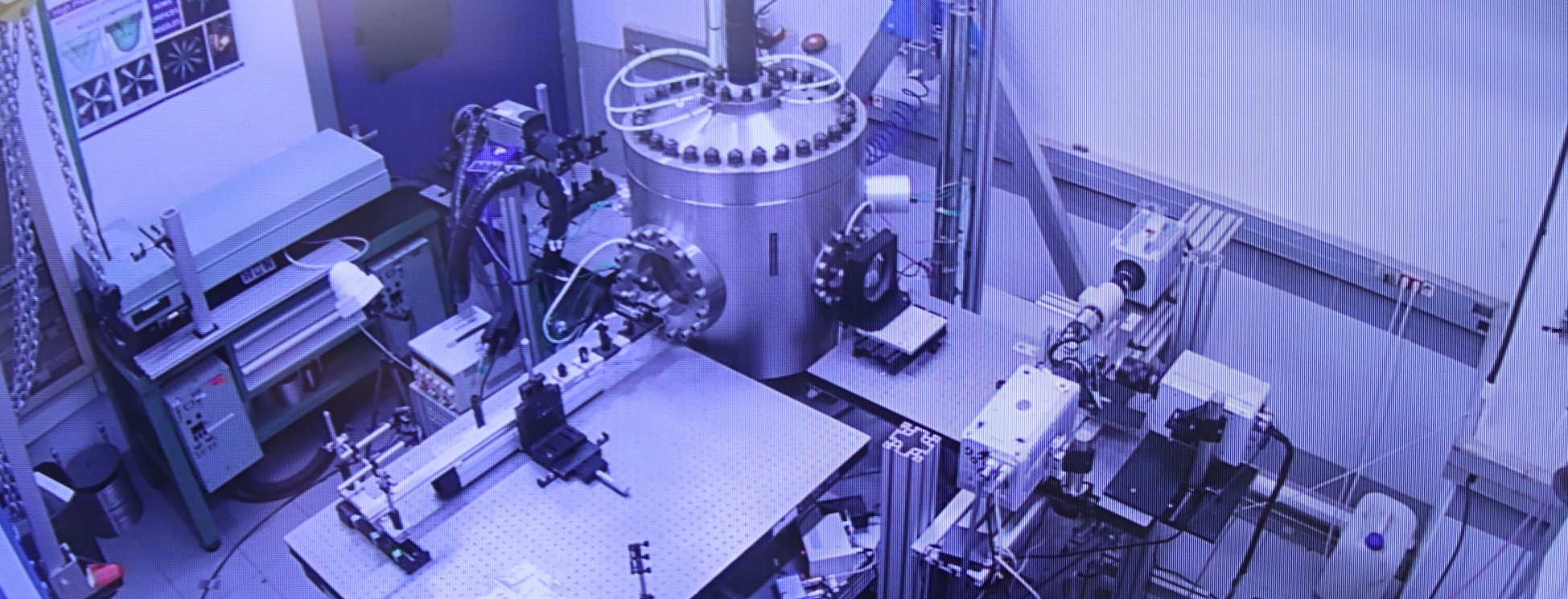

In terms of optical diagnostics, advanced tools for combustion analysis have been used. Those include high speed cameras recoding 25000 images per second to resolve all the information occurring within an injection process, which lasts just 4 milliseconds. The radiation of the flame has been recorded both in the visible and ultraviolet wavelength ranges, from which information on when ignition occurs and what the flame length is has been acquired. Adequate imaging devices allow to determine the time-resolved spread of the fuel in the combustion chamber, as well as the amount of soot particulates formed within the flame. Finally, high-power laser light sources are used to quantify information on the presence of relevant combustion species within the flame. An overview of the optical seutp is shown in Figure 1.

Figure 1 – Experimental facility used to measure the data aimed at model validation. The cylinder in the center is the spray vessel, with different optical accesses and cameras around that make possible to quantify the flame relevant parameters.

In particular, ENERXICO has focused on the following fuels:

- Hydrotreated vegetable oil (HVO), which is representative of sustainable biofuels for compression-ignition engines.

- A blend of Polyoxymethylene dimethyl ethers (OMEx), representative of the so-called e-fuels.

- A reference Diesel fuel, which is the baseline upon which renewable fuels are compared.

While the previous fuels are multi-component, that is, a blend of a large number of species, two additional single component fuels, that is, pure substances, have also been tested:

- OME1, one of the components of the OMEx.

- N-Dodecane, which is a reference fuel within the Engine Combustion Network (ECN, https://ecn.sandia.gov ).

The latter fuels have been chosen because their physical and chemical properties are known, so that single component model validation can be performed in first place before moving to more complex multi-component mixtures.

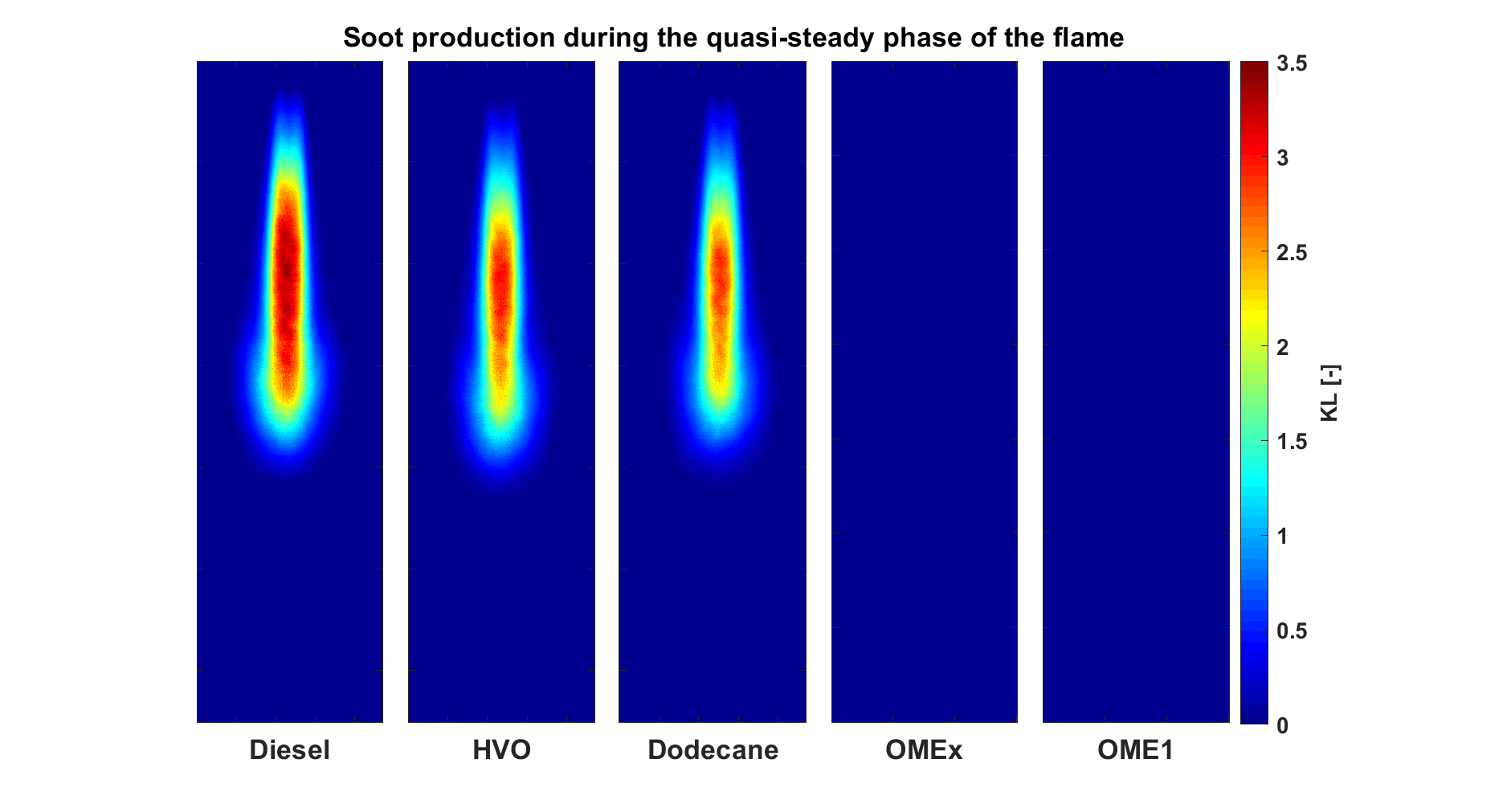

Figure 2 – Comparison of soot production in the investigated flames with different fuels. Images on the right confirm the absence of soot particulates in oxygenated fuels.

Results have shown that HVO performance is quite similar to n-Dodecane in terms of combustion and soot particulate production. This is a relevant information, as it demonstrates that n-Dodecane can be used as a surrogate for upcoming simulations. On the other hand, OMEx and OME1 fuels do not produce soot particulates within the flame (Figure 2) due to their oxygenated content, which is a highly interesting result for their application in combustion systems. Laser diagnostics and flame radiation have also shown a different flame structure of oxygenated fuels compared to conventional ones. Predicting the behaviour of such flames will be a challenging target for the HPC models under development within ENERXICO.