Combustion of fossil fuels is the largest contributor of greenhouse emissions leading to anthropogenic climate change. Liquid fossil fuels in particular are used in all varieties of transportation modes, mainly due to their advantages in terms of energy density, which is critical for mobility applications. Current efforts in transportation aim to replace internal combustion engines with electrical motors in low power applications, such as motorcycles or passenger cars. For larger power applications aimed at the mobility of people such as freight and air transport, doing without liquid fuelled powertrains is more difficult. One possible path is the replacement of current fossil fuels with renewable ones, which may help face the challenge of keeping high energy density with the compromise of CO2 neutrality. According to the International Energy Agency (IEA) predictions, biofuel use for transportation should expand 24% over the 2019-2024 period [1]. This includes both biofuels and power-to-liquid fuels, the so-called ‘e-fuels’, for which combustion characteristics need to be understood so that they can be applied in combustion systems with optimal efficiency and with minimum pollutant emissions.

Within the previously described framework, ENERXICO aims to develop High Performance Computing (HPC) models that enable the quantitative description of combustion for renewable fuels, so that predictable tools are made available to the industry for the design of modern combustion systems. Focus is made on two families of renewable fuels with current interest for industry:

- Hydrotreated vegetable oil (HVO) is representative of sustainable biofuels for compression-ignition engines. This fuel is a good alternative to replace conventional diesel due to the high compatibility in terms of physical and combustion properties. HVO can be produced from a great variety of vegetable oils without compromising fuel quality. Both food and non-food related oils, as well as animal fats can be used as feedstocks to produce HVOs.

- Polyoxymethylene dimethyl ethers (POMEs) are also a promising path for compression-ignition engines. They belong to the group of oxygenates which reduce soot formation in combustion when added to diesel fuels. They can be produced large scale based on gas-to-liquid technology, and this opens the path to produce them from electricity-derived hydrogen, which would result in a fully sustainable path if this electricity is produced from renewable sources.

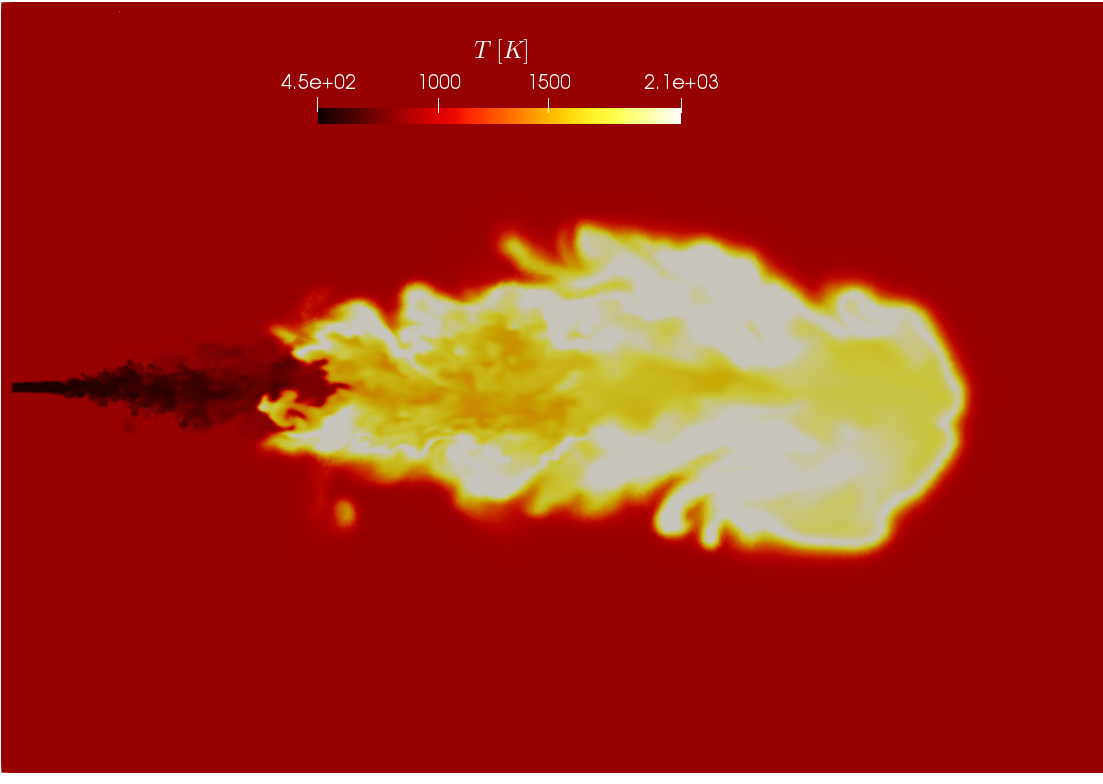

ENERXICO will develop combustion models that predict the combustion process with both types of fuels under compression-ignition engine operating conditions. For that purpose, Alya, a multiphysics code developed by Barcelona Supercomputing Center (BSC) will be used. This code, part of the European PRACE benchmark suite, is an HPC-based tool adapted to run efficiently in large-scale parallel computers. This involves physical modelling, mathematical algorithms and code development and optimization, all with the strong constraint of efficient use of parallel resources. In this case, models will be developed to simulate liquid spray combustion, which is a challenging task, as many complex processes occur within a combustion chamber of any technical combustion system. Liquid fuel is injected and atomizes in small droplets, each of which vaporizes and mixes with air, leading to the formation of an adequate mixture that will burn and release energy. The application of an HPC-based modelling framework is of fundamental relevance to study the development and application of alternative fuels for transportation. The generation of computing models capable of reproducing the complex physics of spray flames under engine-like conditions can reduce the overall cycle of fuel testing and screening. Within ENERXICO, a high-fidelity computational framework is developed to test the aforementioned fuels in a realistic environment. With the increase in computing power, high-fidelity models in the context of large-eddy simulations can be applied to study flame characteristics and pollutant formation. The development of these CFD-based digital twins can be used extensively during fuel design and specification providing fundamental insights of the performance the fuels in practical applications prior testing them in a more costly and complex experimental facility. An example image of a typical flame under engine conditions is shown in Figure 1.

ENERXICO will approach the quantitative description of the multiphase problem of a liquid spray in two ways:

- Lagrangian-Eulerian method, where so-called liquid parcels, made up of a set of droplets, are tracked in a Lagrangian way as they flow along the spray, where air is present and described in a Eulerian fashion. Evaporation models based on droplet description are used to quantify the amount of fuel that vaporizes and hence leaves the Lagrangian phase and is introduced into the Eulerian one, where mixing and combustion will occur.

- Fully Eulerian method, where a mixture of liquid and gas phases is considered at a given point with a diffuse interface, that is, no particular information is given on the geometry of the liquid phase and only the amount of liquid mass is tracked, together with the amount of liquid surface. Evaporation is calculated based upon the local enthalpy present in the liquid-gas mixture.

Both approaches will be implemented in Alya for an adequate description of the liquid spray. A second challenging task will be the description of the combustion reactions and heat release. Technical combustion applications occur in turbulent conditions, where local temperature and composition fluctuate as a consequence of the flow turbulence. As the description of the thousands of species taking part in combustion reactions is computationally very expensive for such a problem, a tabulated approach will be implemented, where a look-up table based on few control variables (mixture fraction, progress variable and scalar dissipation rate) stores the local thermochemical state, and only those control variables are tracked within the flow. To further account for turbulence effects on combustion, both a mean value and a variance of some of these variables are considered.

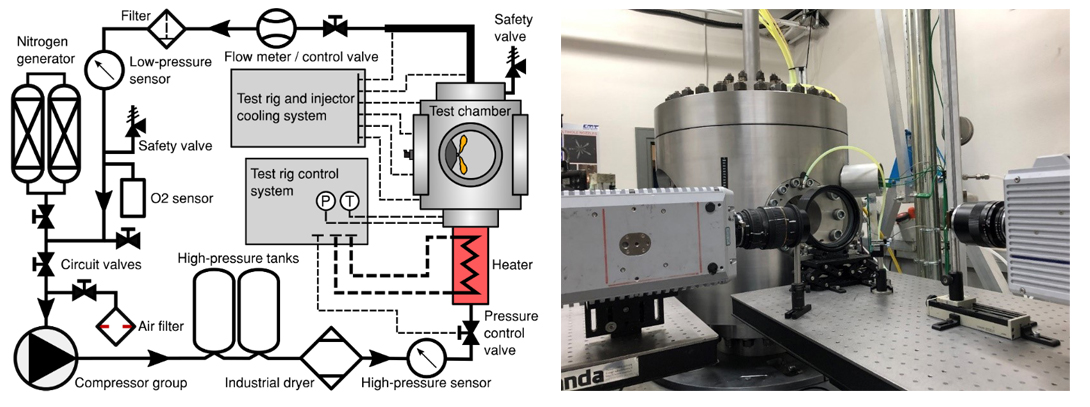

Finally, developed models in Alya will be validated compared to experiments in highly controlled conditions. For that purpose, a high-pressure high temperature vessel will be used (Figure 2), where sprays are injected under engine conditions, prescribed with similar injector orifice geometry and injection pressure, and chamber temperature and pressure (up to 700ºC and 80 bar). Advanced optical diagnostics based upon laser fluorescence and high-speed cameras will be used to quantify spray evolution along the injection process, with a duration of few milliseconds. Parameters such as spray full and liquid lengths, and ignition delay, among others, will be measured for the different fuels (HVO and POMEs) under investigation.

In summary, ENERXICO will contribute to the development of an HPC modelling platform that can be used by industry to gain further understanding of the performance of renewable fuels in practical applications. Advanced experimental tools will be used to validate model predictions. Furthermore, the synergy between modelling and experimental results will contribute to extend the knowledge on the effect of renewable fuels on combustion applications, so that it can be used to develop efficient, clean and sustainable powerplants, in response to the society demands for transportation systems.

[1] IEA (2019), "Renewables 2019", IEA, Paris https://www.iea.org/reports/renewables-2019